Blog

Bridging the Experience Gap: How Technology Can Help Boost the Next Generation of Estimators

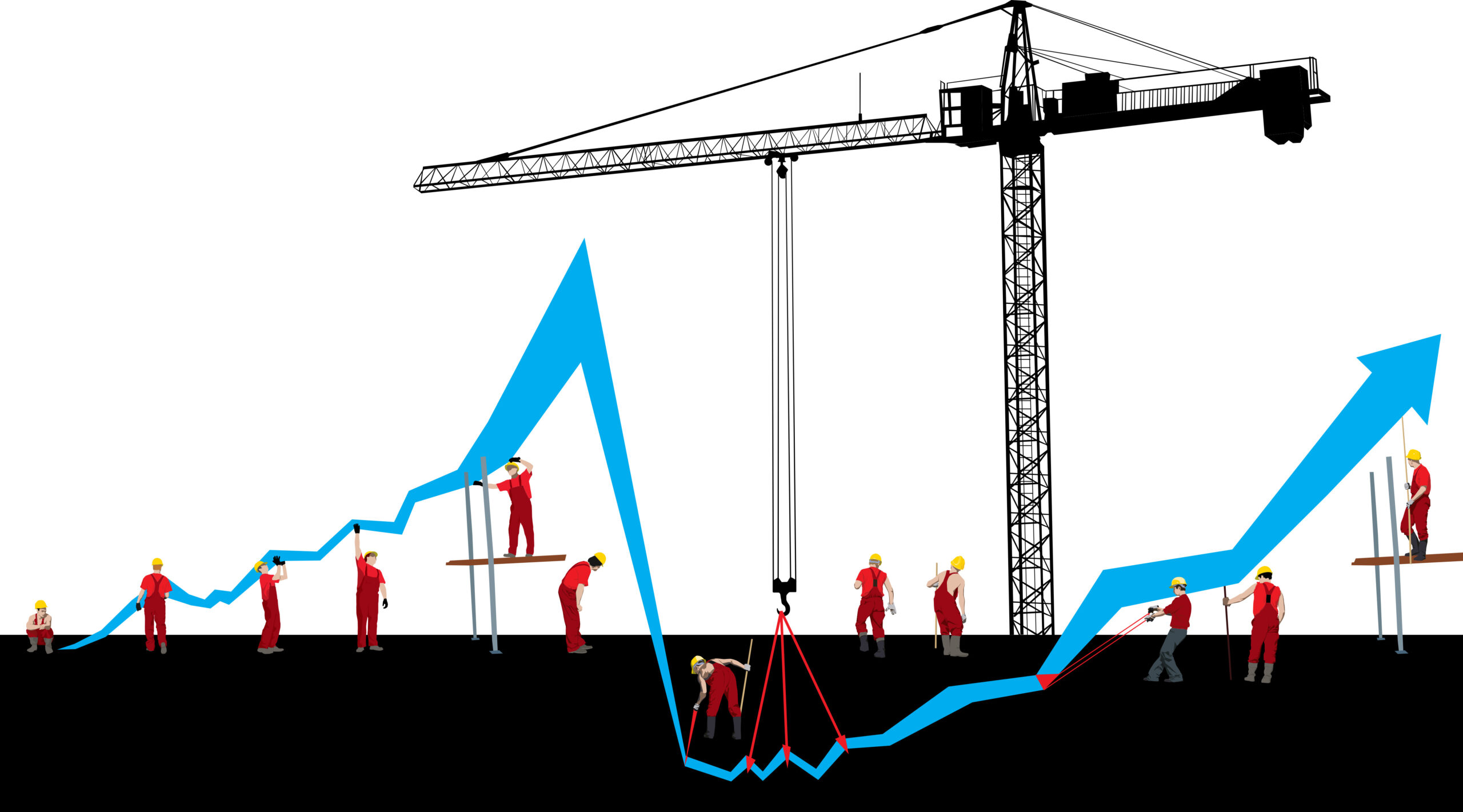

The construction industry is grappling with a labor shortage that is impacting a number of functions, including estimating. As veteran estimators head into retirement, they’re taking decades of irreplaceable knowledge with them. Meanwhile, younger workers face a daunting learning curve that traditionally takes years to master. The result? Companies are struggling to fill critical positions while maintaining the accuracy and speed their clients demand.

The Real Cost of the Skills Gap

Construction estimation requires a unique blend of skills, including technical knowledge, market intuition, and risk management that can’t be learned overnight. Experienced estimators understand how weather delays affect labor productivity, know which subcontractors consistently deliver on their promises, and can spot potential issues in architectural plans before they become expensive problems.

When these professionals retire, the knowledge gap creates real consequences. Project bids become less competitive, cost overruns increase, and client relationships suffer. In an industry where margins are already razor-thin, these estimation errors can have a significant impact on business profitability.

The Domino Effect

The pressure is mounting as projects grow more complex, incorporating new building methods, sustainable materials, and advanced technologies that push the limits of traditional estimation methodologies. The ripple effects extend throughout the entire construction ecosystem.

General contractors lose credibility with clients when estimates consistently miss the mark. Subcontractors face project delays when material quantities are miscalculated. Even suppliers feel the impact when purchase orders swing wildly between projects due to inconsistent forecasting.

What starts as a few inaccurate estimates quickly becomes an efficiency problem that affects everyone from project owners to specialty contractors.

Technology as the Great Equalizer

While nothing can replace human expertise, technology is stepping up to level the playing field. Technology helps firms bring new estimators up to speed faster than has previously been possible. AI and digital tools give newer estimators access to insights that would typically take years to develop.

AI-Powered Takeoff Revolution

AI-driven takeoff software can now analyze digital blueprints in minutes, automatically identifying and calculating material quantities with remarkable precision. These systems use machine learning algorithms to recognize patterns and details in construction documents that human eyes might miss, cross-referencing drawings, specifications, and data to ensure nothing gets overlooked.

What used to take weeks of manual review can now be completed in a fraction of the time. The accuracy of these systems is just as impressive as the time savings – AI-powered takeoff solutions can detect, label, and measure individual components in seconds, dramatically reducing the risk of costly oversights that often plague manual takeoffs.

Smart Data and Predictive Analytics

Machine learning systems are also revolutionizing how we build and maintain estimation databases. These platforms analyze thousands of completed projects to identify patterns that even seasoned professionals might miss. They can predict labor productivity based on everything from crew composition to weather patterns and project characteristics, giving new estimators data-driven insights that would traditionally require years of field experience to develop.

Estimators can now access real-time pricing platforms, so they no longer need to spend years building supplier relationships to access current market rates. Cloud-based systems provide instant access to updated material costs, track market fluctuations, and alert users to significant price changes that could impact project profitability.

Some advanced systems even use predictive analytics to forecast costs based on market trends, availability, and logistics, helping companies make smarter purchasing decisions before material shortages or price spikes hit.

Accelerating the Learning Curve

Technology is also transforming estimator training itself. Interactive simulation platforms let new hires practice on virtual projects without the risk of costly real-world mistakes.

Virtual Training Environments

These systems can present hundreds of different scenarios—from straightforward residential projects to complex commercial builds—giving trainees exposure to situations they might not encounter for years in traditional practice. A new estimator can now experience pricing challenges from different geographic markets, various project types, and multiple economic conditions all within their first few months on the job.

This accelerated exposure builds confidence and competence at a pace that was previously impossible. New estimators can learn from mistakes in a risk-free environment, building pattern recognition skills at a much faster rate than they would if they relied solely on real-world experience.

Breaking Down Knowledge Silos

Collaborative platforms are also breaking down knowledge silos within organizations. New estimators can tap into their company’s collective wisdom, accessing historical project data, learning from past successes and failures, and benefiting from specialists across different trades and markets.

Sharing this institutional knowledge accelerates professional development like never before. Building Information Modeling (BIM) integration has transformed the takeoff process from a manual, error-prone activity into a precise, automated workflow. New estimators can generate accurate quantity takeoffs directly from 3D models, reducing the risk of missing components or miscalculating volumes.

Doing More with Less

Technology helps teams improve productivity and frees up time for higher-value activities such as risk assessment and strategic pricing.

Integrated scheduling tools help estimators understand the labor and equipment implications of their decisions. While advanced analytics provide visibility into estimation performance, helping teams identify improvement opportunities and track their progress over time.

Modern platforms enable teams to collaborate seamlessly, combining expertise from different locations and specialties. An estimator in one region can instantly access insights from colleagues who’ve handled similar projects in other markets, breaking down geographic barriers that once limited knowledge sharing.

Integrated Solutions

When estimating systems connect with project management and accounting platforms, they create feedback loops that were previously impossible. Estimators can see how their predictions compared to actual costs and adjust their approaches accordingly. This enables continuous improvement, helping teams become more accurate and competitive with each project.

Real-time collaboration features also mean that multiple specialists can contribute to complex estimates simultaneously. While one team member focuses on structural elements, another can handle mechanical systems, and a third can assess site-specific challenges—all working within the same digital environment with instant visibility into each other’s work.

The Road Ahead

The future of estimating technology will deliver even more sophisticated tools. Emerging technologies such as predictive analytics, AI, and virtual and augmented reality will continue evolving and improving, offering insights that in some regards surpass even the most experienced human estimators. But the most successful organizations will be those that view technology as an enhancement, not a replacement, for human judgment and knowledge.

Businesses that adapt new technologies to successfully bridge the experience gap will build more resilient teams, deliver more predictable outcomes, and position themselves for sustainable growth in an increasingly competitive market.